- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Quid commoda pulvis remotionem molere tables ad plastic processus societatibus?

2025-05-08

Botou Xintian environmental Praesidium Equipment Co., Ltd.est a manufacturer et venalicius.

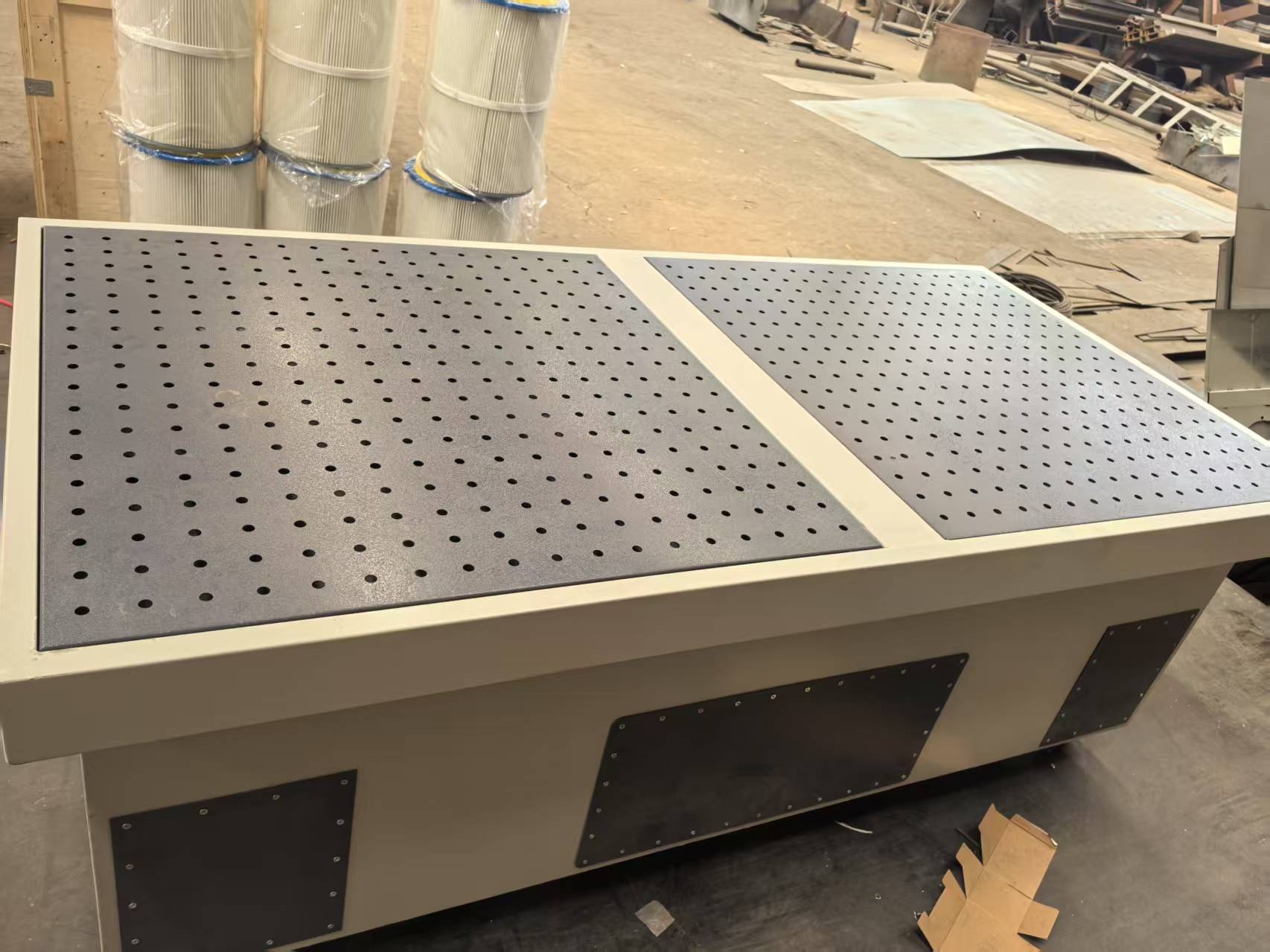

Et pulvis remotionem molere tables sumus producendum sunt flexibile, sublimem pulvis amotionem accurate, et facilis esse ponere.

Et pulvis remotionem molere tables multa commoda in plastic dispensando societates, quae maxime reflectitur in sequentibus puncta:

- Certain molere:Et pulvis remotionem molere mensam potest providere summus praecisione molere effectus. Secundum ad diversas necessitates plastic processus, in plastic rudis materiae vel products potest esse humus ad specifica particula magnitudine et figura ad curare productum magnitudine accurate et superficiem, quod adjuvat ad producendum, et accurate per axis et particulas mole distributions secundum diversas axis et particulas mole distributions secundum diversas axis et particulas distribution secundum diversis plastic dispensando. In summus celeritas agitur gradiente molere discus forms a variabilis pressura agro in contactu superficiem, ut polymer matrix potest directional Conscidisti secundum preset iniqua dimensional et superficies.

- Remove impudicitiis: et aedificavit in airflow stratification fabrica construitur negativa pressura vortex in adtritis area et capturostatic ad particulas in realis tempore per combined actiones electrostatic adsorption et inertia separationis, claudebant et crux contagioni. Hoc synchronum purificationem mechanism effectibus excludit superficiem microcerks et internum accentus concentration puncta, ut optical uniformitatem et structural integritas in ultima uber occursum ipsum application signa.

- Redigo pulveris pollutio:Magna moles pulvis erit generatur in plastic processus processus. The dust removal grinding table is equipped with an efficient dust removal device that can collect the dust generated during the grinding process in time, reduce the dust concentration in the working environment, meet environmental protection and occupational health and safety standards, create a clean and healthy working environment for employees, and reduce the harm of dust to employees' respiratory system, etc.

- reducere ignis metus:Plastic pulveris est flammabiles et explosivae substantiam. Cum ad quandam retrahitur in aere, facile est causa explosion vel ignis cum occurrit ignis fons. Et pulvis remotionem molere mensa reduces concentratione plastic pulvere in officina per opportune pulvis remotionem, ita valde reducendo periculo salute accidentia ut ignis et explosione et inceptum salutem.Plana vacuum Sanding tablesAge tutum productio limina imperium polymer materiae per constituendum dynamic statera mechanism ad pulvis concentration. Suspendisse plastic particulas habere humilis mico punctum characteres debitum ad incrementum in specifica superficiei area et sui ipsius sustentans combustione tendentia est exponentially amplificari in turbulento environment. The nano-scale debris generated by the grinding process enters the gas-solid separation device through negative pressure drainage, so that the dust load in the working area is always below the critical point of deflagration.

Synergistic effectus multi-scaena cyclone separator et electrostatic neutralization moduli non solum cuneos continua distributio pulveris nube, sed etiam excludit per ignitionem periculo per frictional static electricity exacta. Vestibulum Vestibulum Vestibulum Diversus Vestibulum Sensor Triggers in Airflow ultricies mechanism ad curare ut dolor concentration in clausa ratio deviat ex oxidizing environment requiritur ad liberum radicalis catena reaction. Hoc dual praesidium ratio activae tutela et passiva suppressionem efficenter disintegrates quattuor elementum copulata conditiones pulveris et aedificat in intrinseco salus obice a fons industria release.

- amplio productio efficientiam

- Integrated Operatio:With a integrated operation, modern dust removal grinding tables are usually designed as integrated equipment, integrating grinding and dust removal functions, reducing the equipment's footprint and the intermediate links in the production process, allowing plastic processing companies to more efficiently layout and organize production, and improve overall production efficiency.

- continua et firmum operationem:High-qualitas pulvis remotionem molere mensam habet princeps reliability et stabilitatem, potest currere continuously diu, et redigendum downtime fecit per apparatu defectum. In eodem tempore, eius altum gradum automation potest animadverto automatic loading, molere et unloading operationes, redigendum manual labore intensionem et amplio productio efficientiam.

- reducere rudis materia vastum:Per praecise molere imperium et immunditia remotionem, in pulvis remotionem molere mensa potest amplio utendo rate de plastic rudis materiae, reducere in vastum rudis materiae causatur a simpliciter rudis materiae vel inactum molere, et sic reducere et rudis materiae, et sic reducere costs.

- Redigo apparatu sustentationem costs:due to the good dust removal effect of the dust removal grinding table, the wear and corrosion of dust on other parts of the grinding equipment is reduced, the service life of the equipment is extended, and the maintenance and replacement costs of the equipment are reduced. In addition, bonum opus environment et adjuvat ad redigendum in defectum ex aliis productio apparatu fecit per pulveris pollutio, ulterius salute in comitatu scriptor apparatu sustentacionem costs.